Reloading can sometimes feel like a complicated math problem—long and maybe even a little scary. When troubleshooting or searching for improvements, it’s crucial to focus on one step at a time. Even within a single stage of the process, the number of factors at play can be overwhelming.

Take a seemingly simple step like bumping the shoulder on your cases. What factors work together to produce an industry-standard .002” shoulder bump?

- THE DIE

- When Forster machines their sizing dies, they are precisely cut .127” shorter than a SAAMI minimum chamber. This accounts for the .125” industry-standard shell holder thickness plus an additional .002” to achieve the correct shoulder bump. Also, the die’s interior finish plays a crucial role in ensuring proper and consistent sizing.

- THE SHELL HOLDER

- While the industry standard thickness is .125”, manufacturing tolerances exist. For example, Forster Co-Ax press jaws have a .125” – .002” tolerance, meaning they could be .123” thick. If a shell holder has a plus tolerance, it can impact shoulder bump.

- THE RIFLE

- If your rifle’s chamber is larger than the SAAMI minimum, setting the die to the shell holder will result in a shoulder bump greater than the standard .002”. On the other hand, many gunsmiths cut chambers tighter than SAAMI minimum, which can impact a tightly cut die’s ability to properly bump the shoulder.

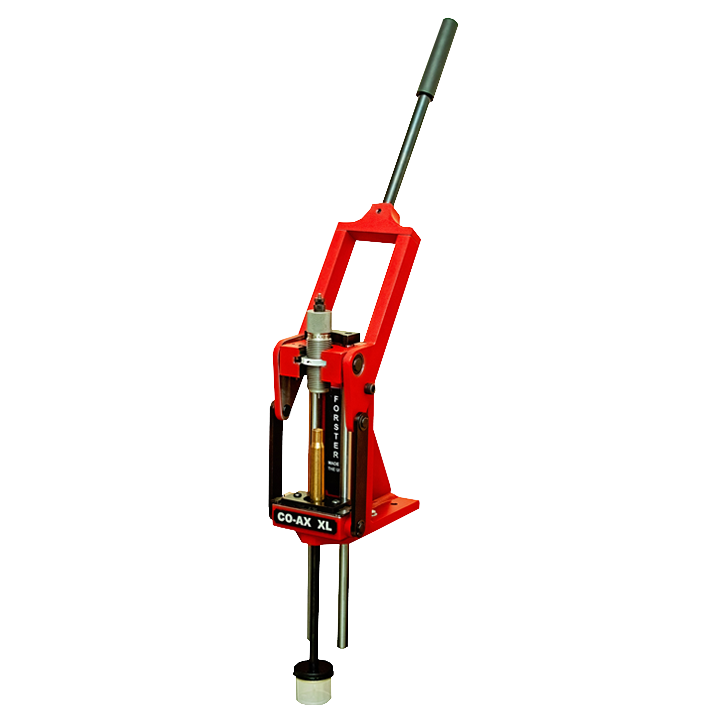

- THE PRESS

- Every press has built-in tolerances within its linkage. To allow a pin to fit and pivot properly, a minimum .001” clearance is required. While bottoming out the press against the shell holder can minimize this play, wear over time may alter the press’s mechanics. As a result, the die’s height may need to be adjusted to maintain the same shoulder bump.

- CASE LUBE

- Case lube buildup, inadequate application, or improper timing can influence how brass releases from inside of the die. Even if cases aren’t sticking, insufficient lube could prevent proper sizing.

- THE BRASS

- Variations in brass hardness and shoulder angles can affect how the shoulder bumps. Additionally, if the neck walls are thick, an expander that overworks the brass can pull the shoulder back out during the upstroke.

And that’s just the beginning! What is the tolerance of the angle on the reamers used to cut both the sizing die and the rifle? What is the angle tolerance of the headspace gauge used to chamber the rifle? Factors like reamer angle tolerances and headspace gage accuracy also play a role.

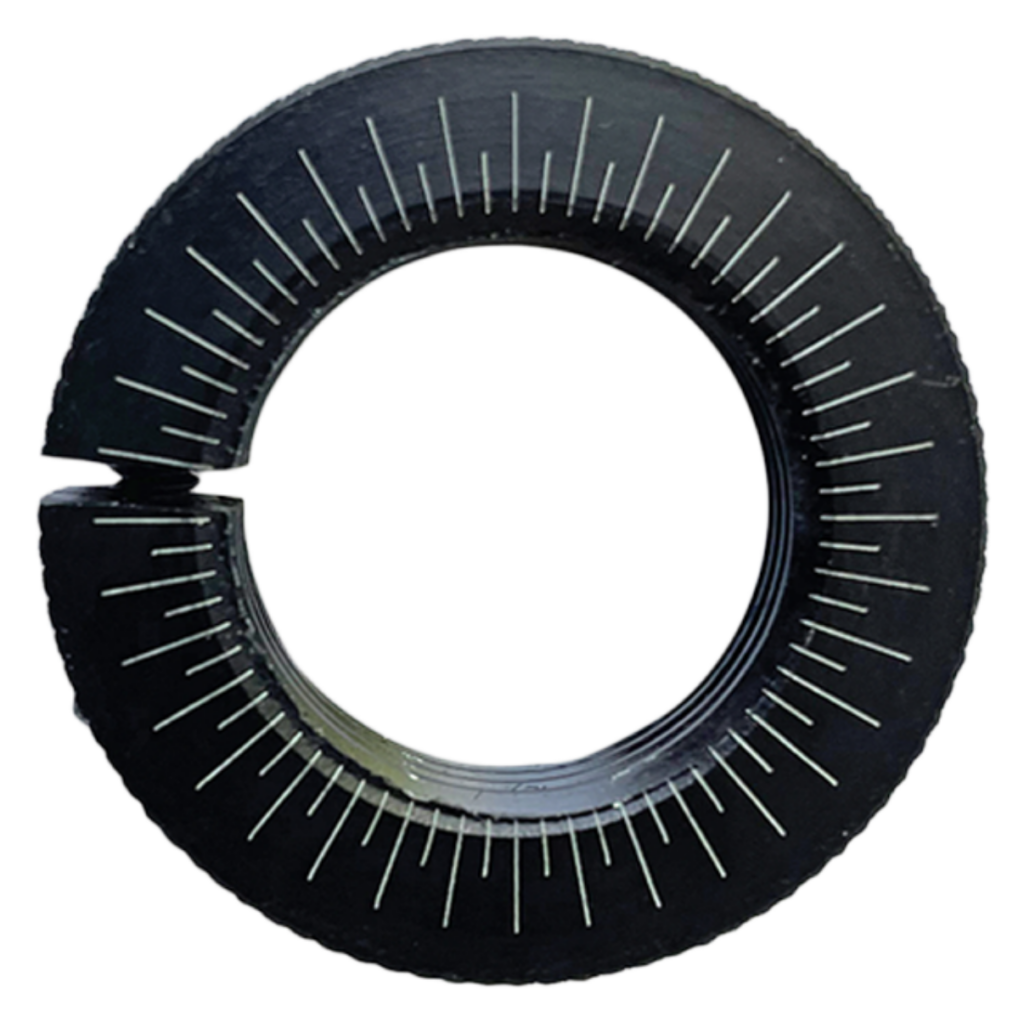

Tools like the Datum Dial Kit are essential for determining the relative bump, and the Accu-ring (included with our Bushing Full Length Dies) can be very helpful in achieving accurate results.

Datum Dial Kit

Accu-Ring Die Lock Ring

What may seem like a simple process actually involves many factors working together to make it possible. It’s remarkable how consistently everything functions as it does! The key is to stay consistent with your process and remain open-minded. What works for one combination of die, brass, powder, and press may not be the right formula for another.

To keep yourself from going absolutely insane, embrace the challenge and only look at one thing at a time!

100 + (130 x 5) = 750

130 + (100 x 5) = 630