Getting into reloading can feel overwhelming, but we’ve put together a comprehensive guide to help you get started with confidence. Whether you’re a beginner or looking to refine your process, this list will provide clarity on what you need and what can enhance your reloading experience.

The Essentials: What You Need to Reload

To successfully reload, you’ll need the following key items:

- Press: The staple to reloading (click to view)

- Standard Die Set: Includes a full-length sizing die and a seating die for your chosen cartridge.

- The sizing die ensures your brass is resized to SAAMI specifications for proper chamber fit.

- Our Benchrest Seating Die features a body sleeve and a tight-fitting bullet channel for precise, straight seating. The main difference between this and our Ultra Seating Die is the adjustment method: the Ultra Die uses a micrometer top for fine-tuning, while the Benchrest model adjusts via a lock nut and threaded stem.

- We offer a custom honing service for Forster Full Length Sizing Dies to match your specific brass dimensions.

- Lube: A quality lube is essential for sizing brass, preventing cases from getting stuck in the die. You can apply lube using a roll-out pad or by dabbing a small amount on your fingers and evenly coating the brass before resizing. Consistency in application is key for uniform sizing. (click to view)

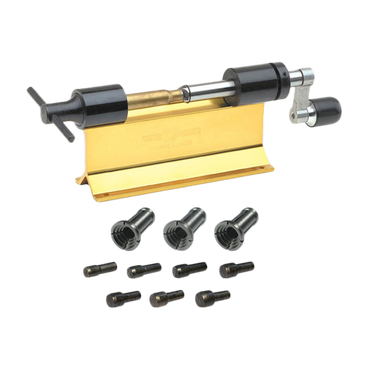

- Trimmer/Debur Tool: Essential when brass stretches beyond the proper length for your chamber. While new brass is typically short enough, fired and resized cases can stretch over time, requiring trimming to maintain consistency. Deburring smooths out sharp factory edges, ensuring easier bullet seating without scratching the jackets or increasing seating force. Hand deburring can be tedious, especially when processing large batches, making a power trimmer a valuable upgrade.

- Calipers: Essential tool for reloading, used to measure neck diameter, case length, base-to-ogive, base-to-shoulder (for shoulder bump/headspace), overall cartridge length, and more.

- Investing in a quality set is highly recommended. (click to view)

- Primer Seater: Used to insert primers into cases, the Co-Ax press comes with a priming function that ensures proper seating depth for reliable ignition.

- Powder Thrower: Effective for measuring and dispensing powder. (click to view)

- Scale: Essential tool for reloading, used to measure and trickle powder.

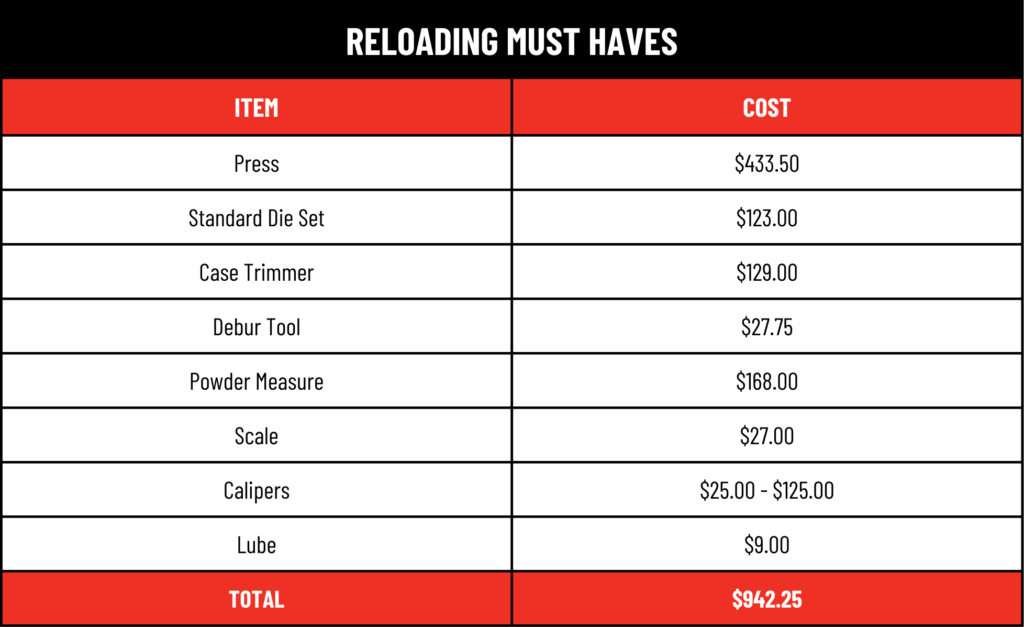

The below table is the bare minimum items you’d need to start your venture in reloading and the total price:

Nice-to-Haves: Upgrade Your Reloading Experience

If you’re looking to optimize your reloading setup, these tools can take your precision and efficiency to the next level:

- Ultra Die Set: For more control than the Standard Die Set, our Ultra Die Set includes a bushing full-length sizing die, allowing you to fine-tune neck tension and minimize brass wear using interchangeable bushings. (click to view)

- Power Trimmer: Hand deburring can be tedious, especially when processing large batches, making a power trimmer a valuable upgrade. (click to view)

- Datum Dial/Comparator: Provides bullet and headspace comparators for precise base-to-ogive measurements when finding lands or testing seating depth

- In addition, it measures base-to-shoulder dimensions after firing, helping adjust the sizing die for optimal shoulder bump (typically .002”-.003”) to ensure safe, reliable feeding without excessive brass wear or dangerous headspace issues.

Datum Dial™ Kit

- Bench Mounted Primer Seater: While many presses include a built-in priming function, a bench-mounted primer seater, like the Forster Bench Mounted Primer Seater, offers a more precise, efficient, and ergonomic way to seat primers, especially for high-volume reloading. (click to view)

- Scale: On the high end, advanced setups like the A&D FX120i scale with an AutoTrickler can cost thousands but offer extreme precision.

- 3-in-1 Case Mouth Cutter: A great addition to the Original Case Trimmer, trimming, chamfering, and deburring in a single step for increased efficiency.

- Neck Tension Gage Set: Available individually by caliber or as a set, to ensure precise control over neck tension.

- Annealer: This is a debated reloading topic. We believe annealing is a key step in achieving consistent ammo, with the AMP Annealer being the most precise method available. (click to view)

- Tumbler: Useful for cleaning brass

- If you don’t have one, you can simply wipe off sizing lube with a towel. We prefer dry tumbling, as it effectively removes all lube before powder charging or bullet seating. It’s especially important to ensure no lube remains before chambering a round, as leftover lubricant can lead to excessive chamber pressure when firing.

- An added benefit of dry tumbling is that it leaves a slight dust residue on the case and inside the neck from the tumbling media. We believe this acts as a natural lubricant, making bullet seating smoother and more consistent with lighter seating forces.

The table below highlights the nice to have options/upgrades alongside essential items, providing a clear comparison between starting with the basics and going all out from the beginning:

Our Reloading Process

As professional PRS shooters and precision enthusiasts, we have developed a reloading process that ensures consistency and accuracy. Here’s a step-by-step breakdown:

- Brass Cleaning & Annealing

- If the brass isn’t excessively dirty from mud or debris, anneal it immediately using the AMP annealer.

- If it needs cleaning, tumble it for an hour to remove major dirt before annealing.

- Lubing & Resizing

- Apply lube and resize using the Forster Co-Ax press and ultra full-length bushing die.

- Aim for a .002”-.003” shoulder bump and .0025” neck tension by selecting the correct bushing.

- Then, allow the expander installed on the bushing die to set the final tension.

- Trimming, Chamfering & Deburring

- After resizing, trim, chamfer, and deburr the necks.

- Then, dry tumble the brass with corn cob media to remove the lube and leave a slight dust coating, which acts as a natural seating lubricant.

- We no longer clean primer pockets, as our testing has shown no measurable impact on accuracy or SDs.

- After tumbling, check flash holes for any lodged media and clear them with a small Allen wrench.

- Priming, Powder Charging & Bullet Seating

- Prime cases using a bench-mounted primer seater.

- Measure and throw powder using an A&D FX120I scale with an AutoTrickler for precision.

- Finally, seat bullets using the Co-Ax press and ultra-micrometer seating die for consistent depth and alignment.

This process helps us maintain high-quality, repeatable results for precision shooting.

We offer all the tools you need, from beginner essentials to professional-grade upgrades. Have questions? Feel free to reach out to us at (815) 493-6360!