With the growing popularity of bushing dies, the importance of outside neck turning has increased. Consistency in neck wall thickness plays a crucial role in achieving precise and repeatable reloads.

Why Outside Neck Turning Matters

When using a bushing die, many reloaders select a bushing .002” smaller than their loaded round diameter to set proper neck tension. Unlike standard full-length dies, which size necks uniformly and then expand the inside, bushing dies only size down the brass. This means any neck wall thickness variation isn’t corrected internally—potentially leading to runout issues when seating bullets.

What Causes Neck Wall Variation?

During firing, the intense heat and pressure cause parts of the brass to momentarily liquefy, allowing gravity to pull small amounts of material to one side. While new brass may have minor variations from the forming process, we don’t recommend outside neck turning new brass.

How Do I Minimize Neck Wall Variation?

There are three primary ways to address this inconsistency:

- Use an Expander Ball:

- Size cases down further (.004” under your loaded round) so that an expander ball corrects inside inconsistencies by pushing the variation back to the outside of your case necks.

- This doesn’t eliminate variation but it’ll push it to the outside, reducing its impact on bullet seating.

- Cut a Tight Neck Chamber:

- A tight chamber minimizes brass flow when fired, reducing variation.

- Outside Neck Turning (Most Consistent Method):

- Removes excess material from the outside of the case neck for optimal uniformity.

- Unlike the first option, which can lead to irregular spring back depending on the brass, outside neck turning ensures uniform neck tension and improved accuracy.

How to Properly Outside Neck Turn

For effective outside neck turning, it’s essential to first expand your case necks to achieve a proper slip fit on the turning pilot. Our pilots are precisely machined to be .0025” under bullet diameter, providing .0005” clearance between the pilot and the case neck. Expanding the necks also ensures that any variation in wall thickness is pushed to the outside, where it can be accurately removed during the turning process.

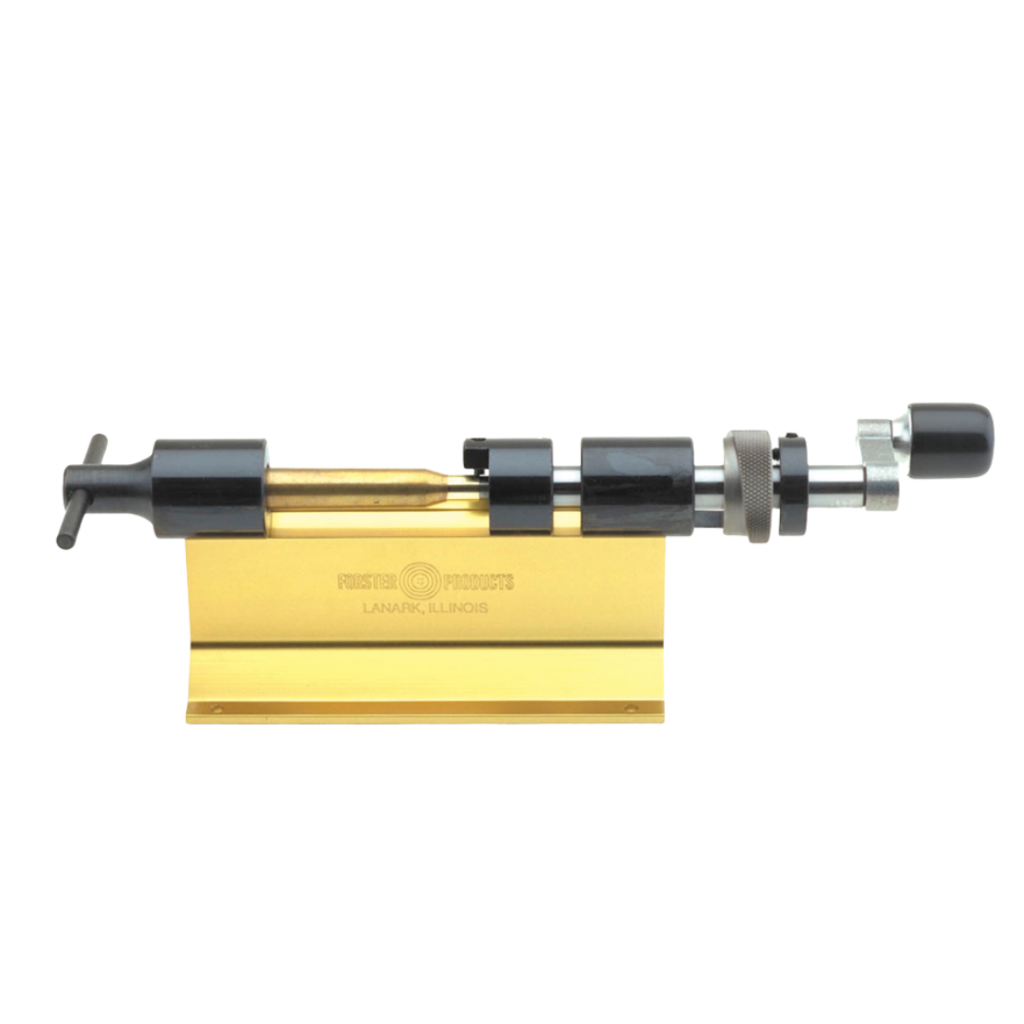

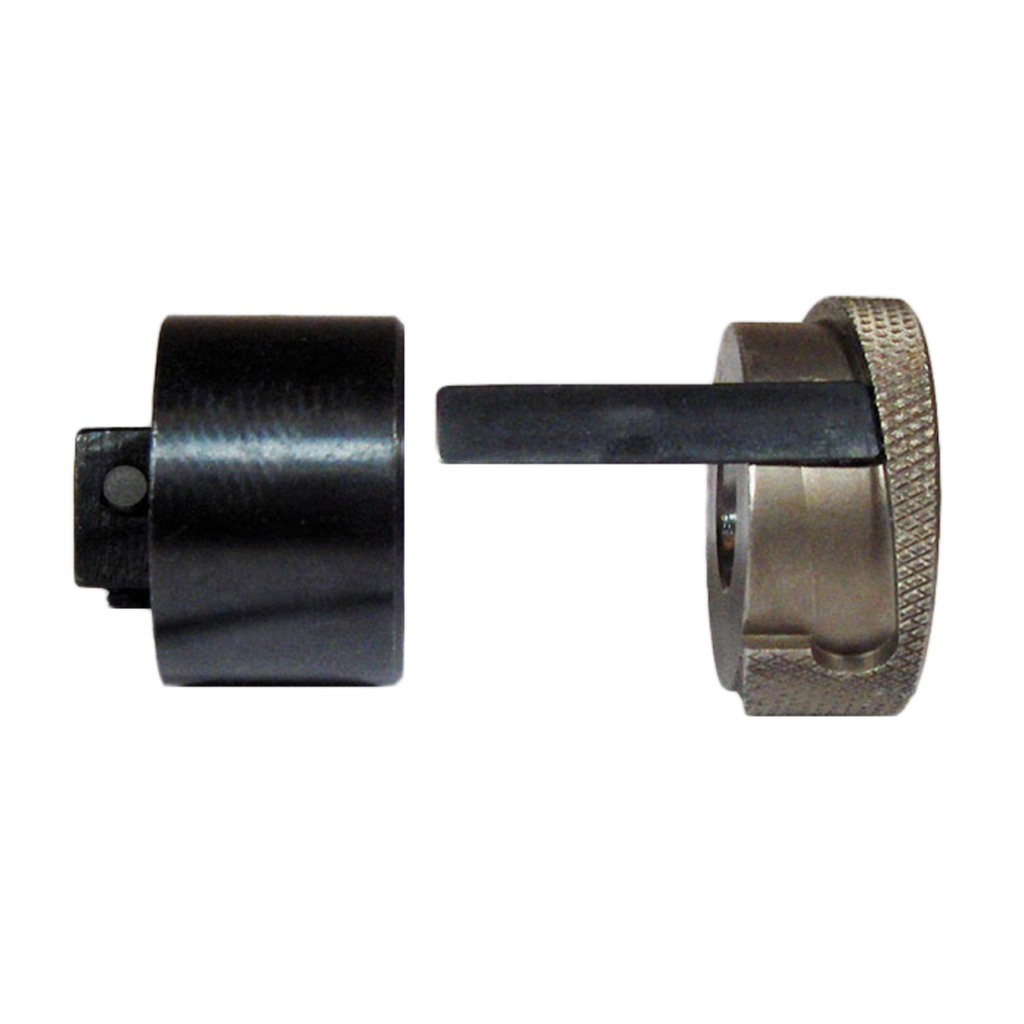

Forster Outside Neck Turning Tools

Forster offers two options for outside neck turning tools: Hand Held Outside Neck Turner (required pilots sold separately) and an Outside Neck Turner (required pilots sold separately). Both are excellent tools, but if you already own a Forster Case Trimmer, the trimmer-mounted unit is the most economical choice, effectively turning your trimmer into a mini-lather for precise and efficient neck turning.

Hand-Held Outside Neck Turner

Outside Neck Turner

If you’re serious about improving reloading consistency, outside neck turning is a valuable process to incorporate. If you have any questions or need help selecting the right tools, feel free to reach out!