Here at Forster Products, we’re always looking for ways to improve our bullet seating dies and address issues reloaders face. One trend we’ve noticed is that as bullets get longer, they have less support under the jacket, which can contribute to seating problems. When designing our seating stems, we test them against some of the most problematic bullets. However, some customers still experience issues, even with bullets we use as benchmarks. This shows that the stem’s profile isn’t always the root cause, so we did some testing to explore other contributing factors!

What We Did

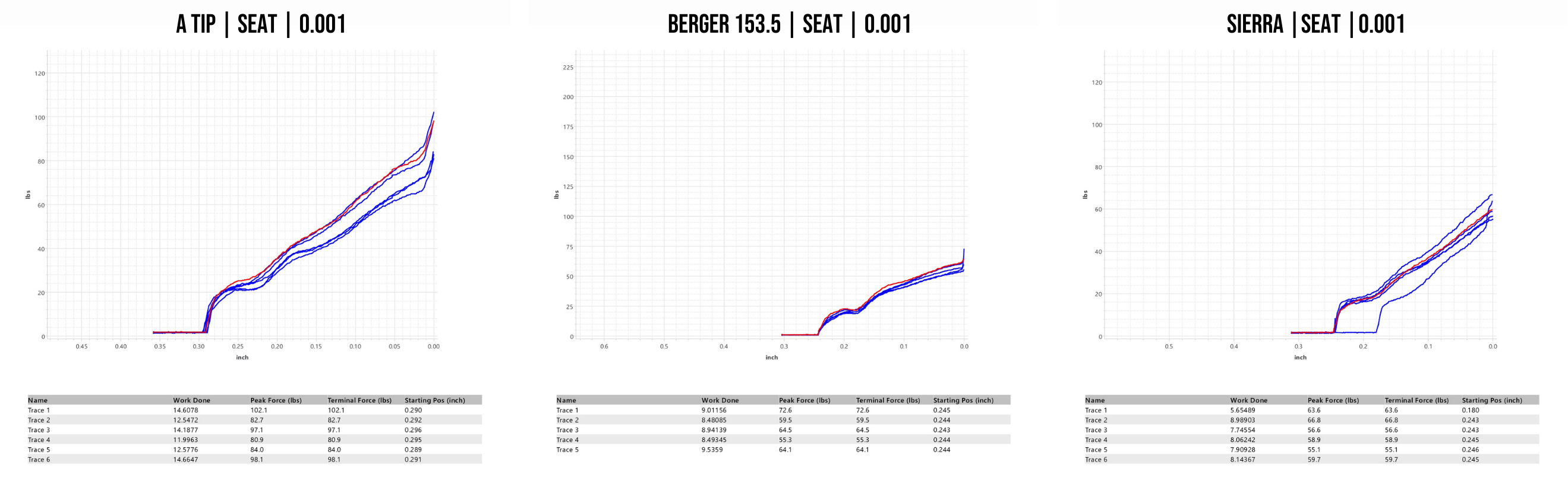

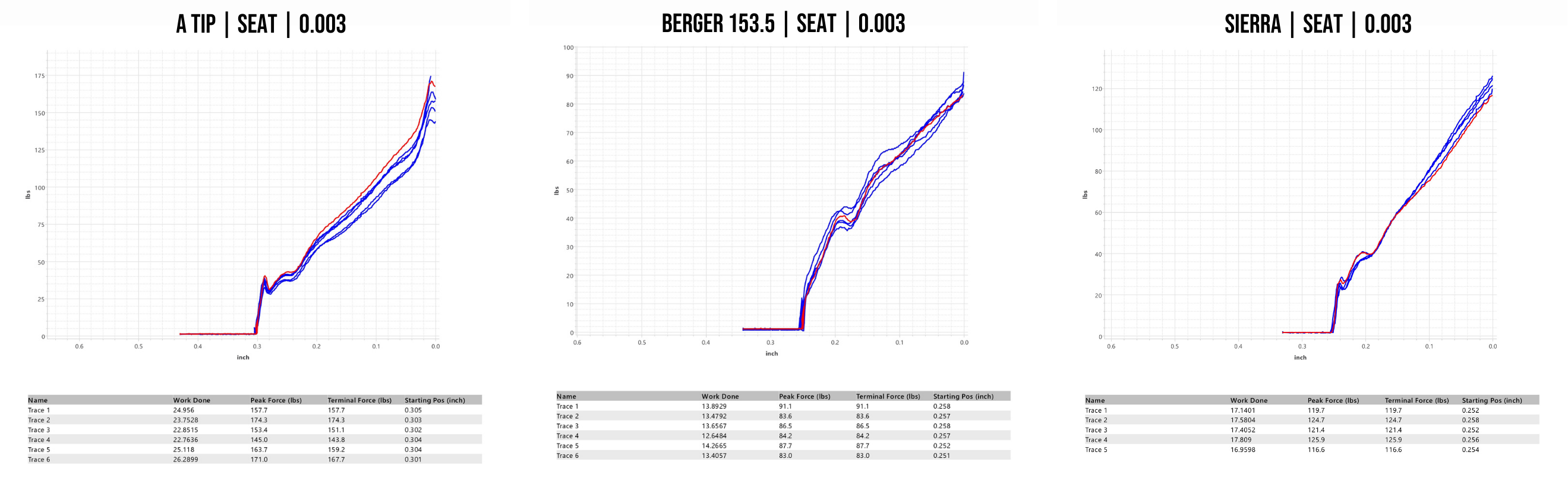

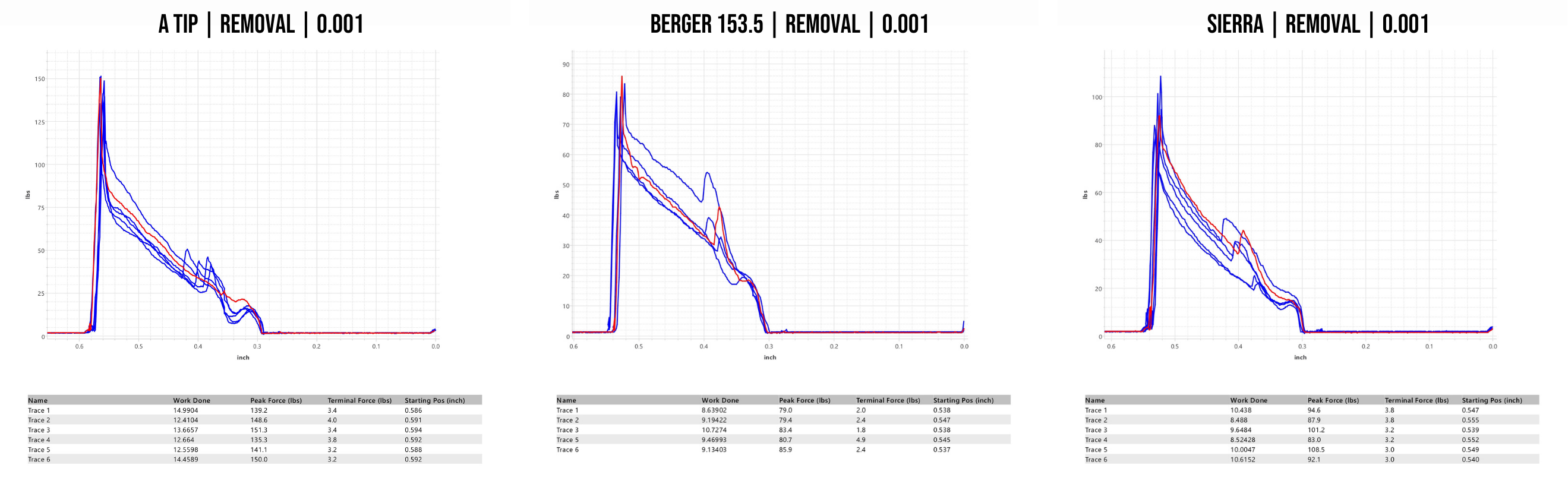

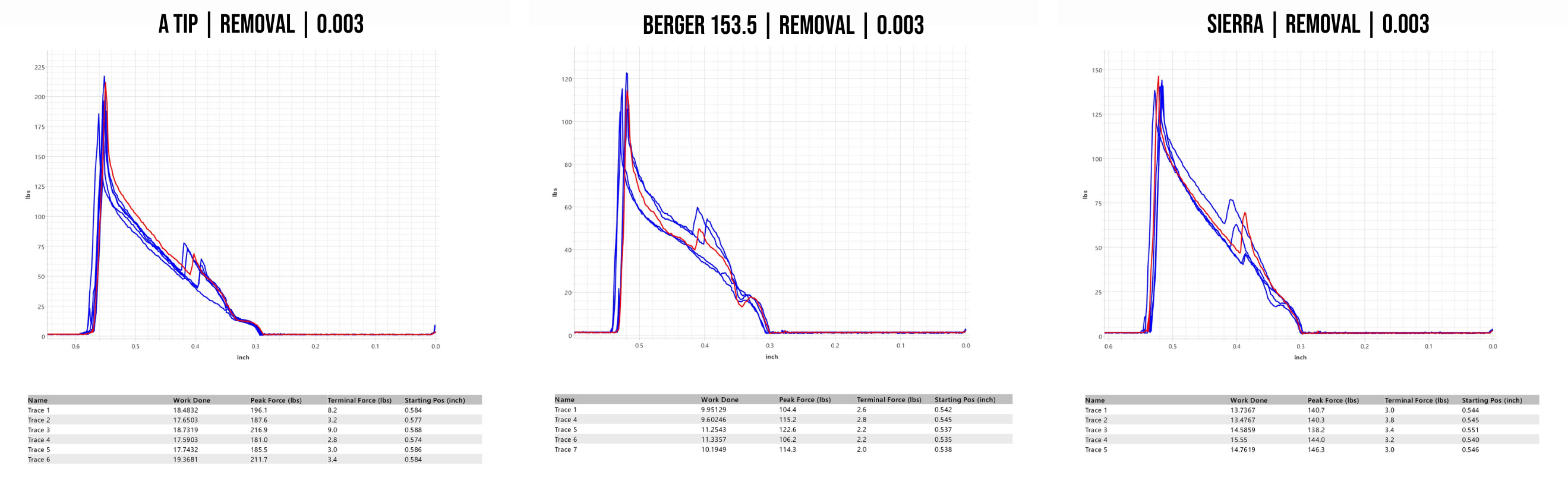

We conducted a test using the AMP Press to measure both the force required to seat bullets and the force required to push them back out. We tested different neck tensions, ranging from .003” down to .001”, across three different bullet types using the same type of brass. Our goal was to determine how neck tension influences seating force and whether reducing tension could help prevent bullet deformation.

What We Found

- Some bullets require significantly more pressure to seat properly, which can lead to impressions forming on the bullet

- Any case requiring over 125 lbs of seating force was more likely to leave a noticeable ring on the bullet.

- Reducing neck tension resulted in lower seating force across the board.

- The force required to remove a seated bullet was consistently higher than the force needed to seat it (by 16%–38%).

- Certain bullets inherently require more pressure to seat, regardless of neck tension.

- Using .001” neck tension kept all our test ammo under 100 lbs of seating force, with fairly consistent seating numbers.

- However, when we tested an even lighter tension of .0005” (half a thousandth), the seating force became very inconsistent. Based on that experience, we wouldn’t recommend going that light.

- This raises a concern when advising people to reduce neck tension. If you’re aiming for .001” but don’t have precise measuring tools or aren’t closely monitoring the results, it’s easy to unintentionally go even lower—closer to .0005”—which could lead to potential issues with consistency and bullet retention.

- However, when we tested an even lighter tension of .0005” (half a thousandth), the seating force became very inconsistent. Based on that experience, we wouldn’t recommend going that light.

Test Results: Force Required to Seat Bullets

Test Results: Force Required to Remove Bullets

What This Means for You

Most reloaders aim for .002”-.003” of neck tension, and if that works for you—great! Keep doing what you’re doing. However, if you’re noticing rings or marks on your bullets (and you’ve already followed our brass prep method), it might be worth experimenting with slightly lower neck tension to see how your rifle responds.

If you’re using a Forster sizing die, the best way to adjust neck tension is by getting a custom expander ball. Our standard expander balls are typically .0015” under bullet diameter, which usually results in .002”-.0025” of neck tension, depending on brass spring back. We also offer oversized expander balls in half-thousandth (.0005″) increments.

To achieve .001” neck tension, you’ll want an expander ball that’s about .0005”-.001” larger than your desired final size. For example, if you need a .263” neck diameter for a 6.5mm round, you’d use a .2635” or .264” expander ball. After spring back, this should leave you at .263”, which is .001” under a .264” bullet, giving you .001” tension.

Keep in mind that different brass types have varying hardness, affecting how much they spring back. Testing with your own brass and using proper measuring tools is essential. To ensure precise neck tension, we highly recommend using our neck tension gage. This will give you an accurate measurement, so you know exactly where you’re at.

What We Found Interesting

Like any test, ours isn’t perfect, and not every result points to a clear solution. However, here are some interesting takeaways:

- Some bullet types naturally require more pressure to seat properly. The force needed to remove a bullet was consistently higher than the force required to seat it.

- Certain neck tensions led to more consistent bullet removal pressures—this could be a potential accuracy sweet spot, but more testing is needed.

- We gained confidence in using certain bullets with .001” neck tension, as they required equal or greater force to remove compared to seating.

Questions Raised And What’s Next

The next question we have is how different neck tensions affect group sizes and velocity consistency. Is this something worth testing further, or are there simply too many variables at play? As experienced reloaders know, changing one factor can improve or worsen results, and adjusting another variable can either fix or further complicate the issue—potentially leading down a deep rabbit hole.

Our next step is to test .001” vs. .003” neck tension while keeping all other factors the same across three bullet types. We will record velocities and group sizes to determine whether these adjustments impact precision or if the primary benefit remains the reduction of bullet denting.

From our initial, limited testing, the answer appears to be yes: reducing neck tension lowers seating force, which in turn helps prevent bullet deformation. With proper measuring tools, reloaders can confidently seat bullets with less tension while ensuring they remain secure and undisturbed.

By making small adjustments to neck tension, reloaders can reduce bullet denting and potentially improve consistency. We’re eager to keep pushing the limits and sharing what we learn along the way!